Find your Products

Find your Sustainable solutions

Complete kits for bottom filling, excl. filling lance.

Max. length 500 mm

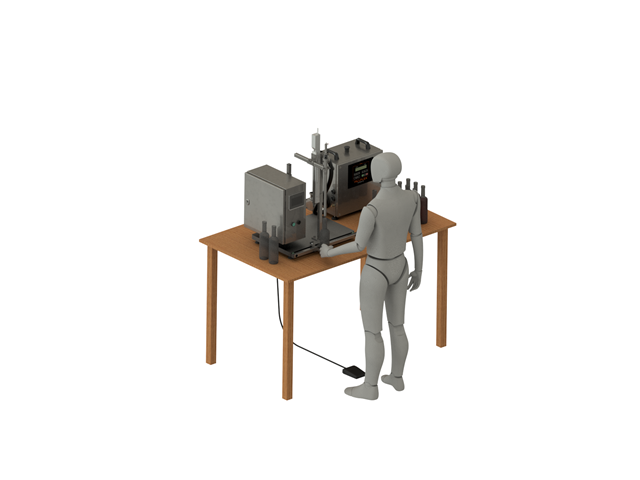

| FF_BFE-TT-00 | Bottom filling, Electric | Table Top, integrated |

| FF_BFE-TT-01 | Bottom filling, Electric | Table Top, separate control cabinet |

| FF_BFE-ST-00 | Bottom filling, Electric | Split Trolley, integrated |

| FF_BFE-ST-01 | Bottom filling, Electric | Split Trolley, separate control cabinet |

| FF_BFE-QP-ST-00 | BFE and queue management | Split Trolley, integrated |

| FF_BFE-QP-ST-01 | BFE and queue management | Split Trolley, separate control cabinet |

| FF_VF-L-25G8-300-V-1 | Dy=ø8 - l=300 mm |

| FF_VF-L-25G12-300-V-1 | Dy=ø12 - l=300 mm |

| FF_VF-L-25G16-300-V-1 | Dy=ø16 - l=300 mm |

| FF_VF-L-25G20-300-V-1 | Dy=ø20 - l=300 mm |

| FF_VF-L-25G25-300-V-1 | Dy=ø25 - l=300 mm |

Communication kit for installation in existing or new machines.

| FF_ACC-CK-01 | Communication kit, for BFE in separate control cabinet |

Complete kits for queue management, incl. gates and photocell/sensor.

| FF_QP-ST-00 | QP queue management, Split Trolley, integrated |

| FF_QP-ST-01 | QP queue management, Split Trolley, separate control cabinet |

Communication kit for installation in existing or new machines.

| FF_ACC-CK-01 | Communication kit, for QP in separate control cabinet |